The HANDi Hand

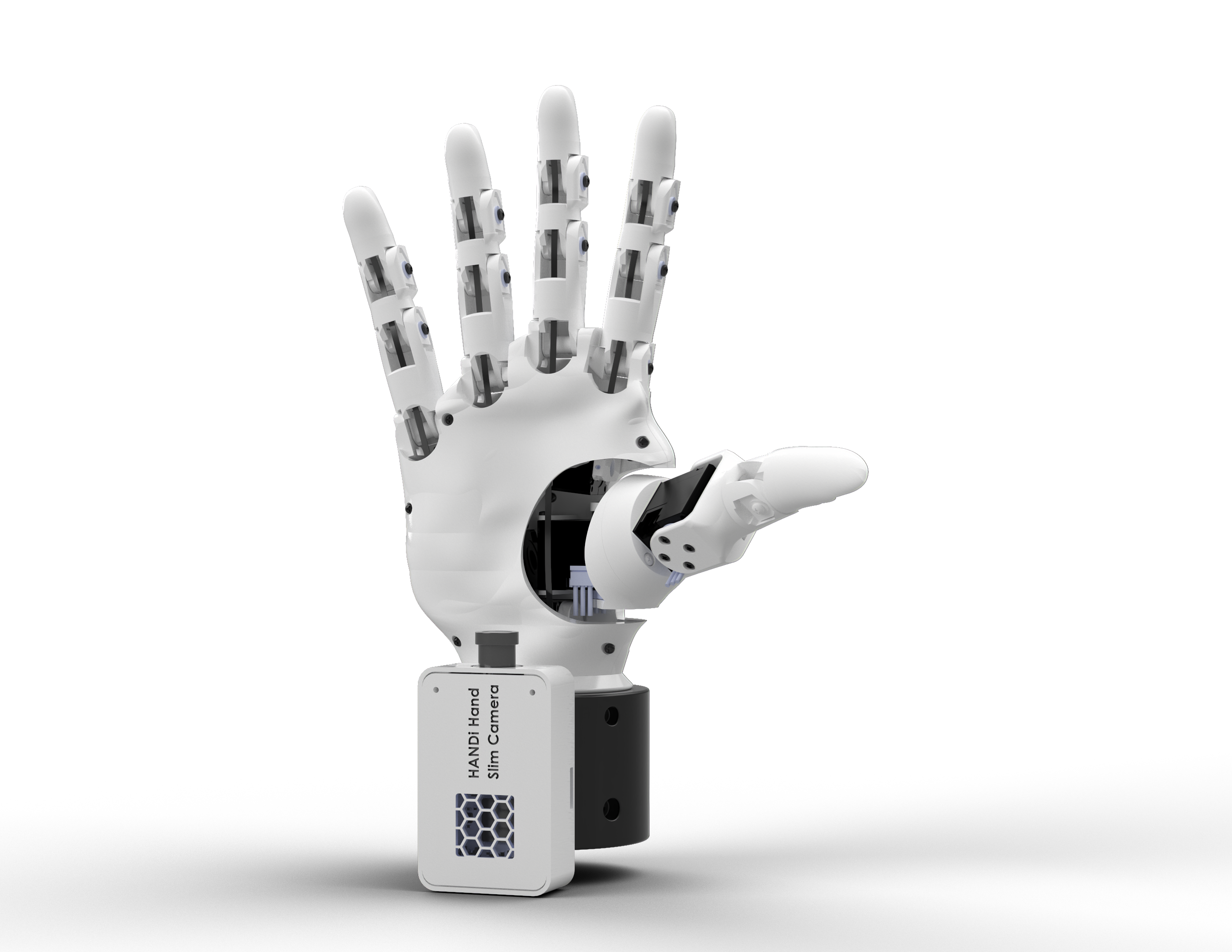

A 3D-printed multi-articulating prosthetic hand designed to facilitate machine learning research that aims to provide more intuitive control of prosthetic limbs.

Project Overview

The Humanoid Anthropometric Naturally Dexterous Intelligent (HANDi) Hand is an open-source, inexpensive, prosthetic hand capable of providing real-time sensory information for machine learning and prosthetics research. Originally designed in 2017 by Brenneis et al. I worked on the newest release of the HANDi Hand which includes updates to make the system more robust for longer-term machine learning experiments.

Key Features

- 6 degrees of freedom (one for each finger, and two for thumb rotation and flexion)

- Brand new motors with integrated sensors (check out how I chose these motors here!)

- Zip tie “tendons”

- Options to include more sensors including a wrist-mounted camera, fingertip sensors, an imu, and joint sensors.

3D-Printed Design

Changes I made from the 2017 version include a complete redesign of the palm and thumb which house the motors. All custom parts of the hand were designed in SOLIDWORKS 2016 research edition which allow for the open-sourced release of not only 3D files but design files as well.

Some design decisions I made:

- Prioritizing ease of printing with parts that require minimal support material.

- Making file management easy with intuitive naming convention for all custom parts.

- Accounting for different 3D printers by including an adjustable variable for plastic shrinkage.

- Balancing blockiness and curvature in the palm to avoid the uncanny valley.

- Replacing thumb rotation from a 3D-printed gear to a bracket driven mechanism for robustness.

The figure below display the six new motors in the HANDi Hand and their respective finger. Here, the bracket driven thumb rotation mechanism is clearly shown.

The two images below show how the thumb flexion mechanism works. I decided to couple the rotation of the motor with the flexion of the furthest thumb joint. This makes clever use of the symmetry of these new motors, reducing the need for additional parts.

Electronics and Software

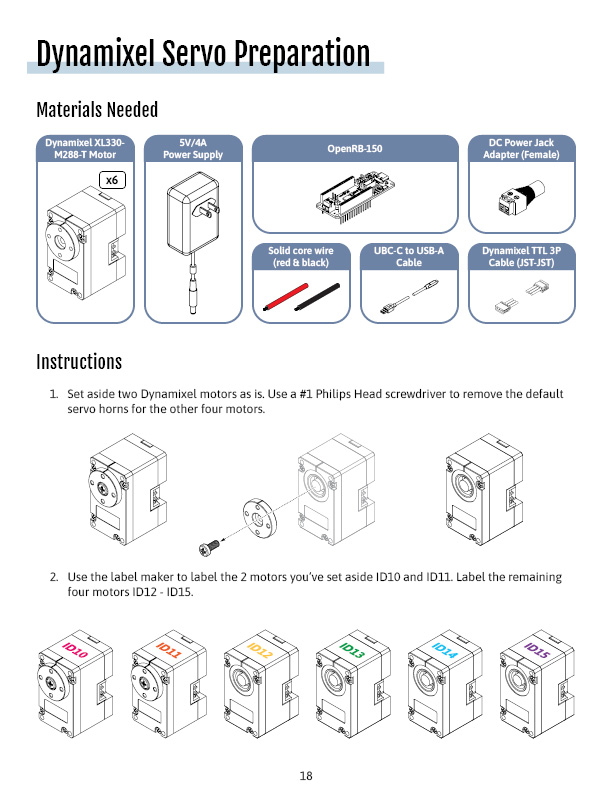

The hand is comprised of six DYNAMIXEL XL330-M288-T servo motors. Each motor can send real-time data such as its position, velocity, temperature, and more. Communication between the computer and motors was established using the Dynamixel Software Development Kit (SDK).

I chose the OpenRB-150 Arduino compatible controller because it features 4 dedicated DYNAMIXEL ports, and supports the DYNAMIXEL testing and calibration software. Its form factor is also slim enough to slip into small case or demo wand for a variety of use cases.

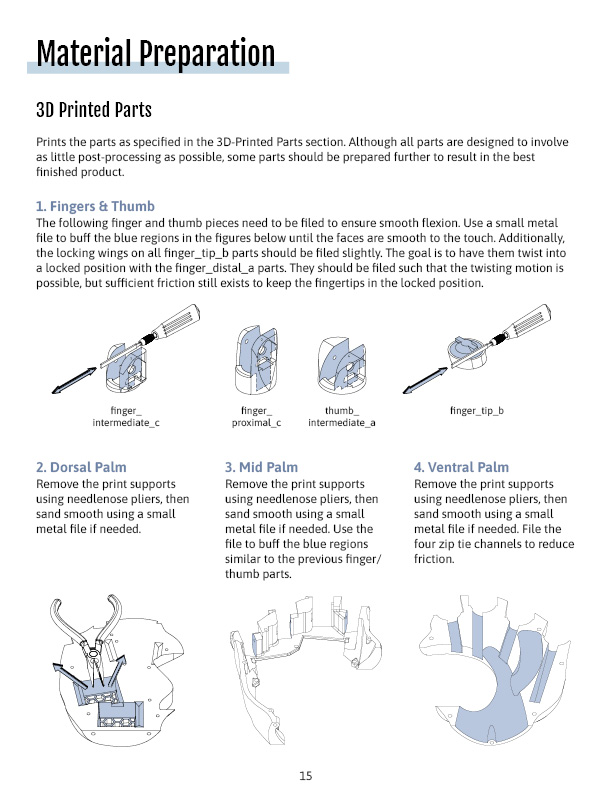

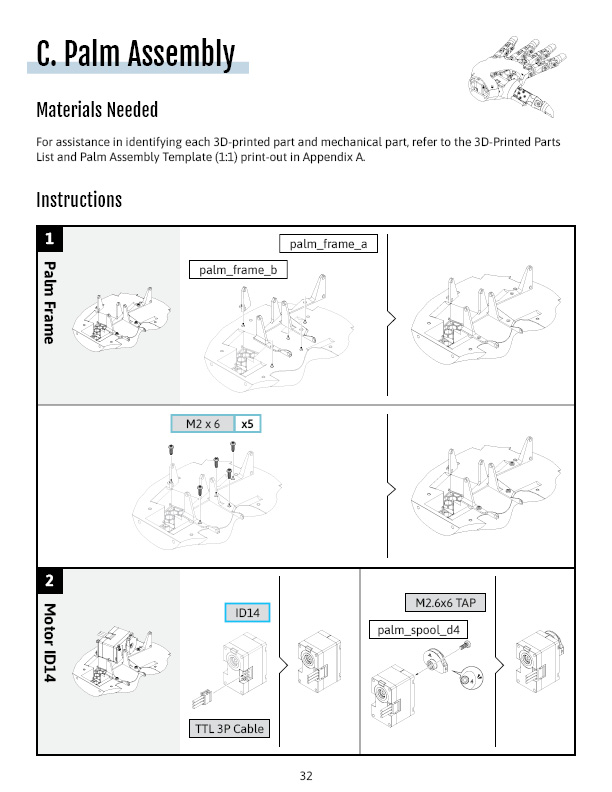

Documentation

I am currently designing an assembly guide which includes instructions on how to make a fully functioning HANDi Hand from scratch. I designed this guide for those, like me, who love to build IKEA, Lego, and Gundam. There are many places in my guide where I drew inspiration from these famous designers. Here are a few snippets of the guide which I am most proud of. This guide was designed with Adobe Illustrator, InDesign, and Photoshop.